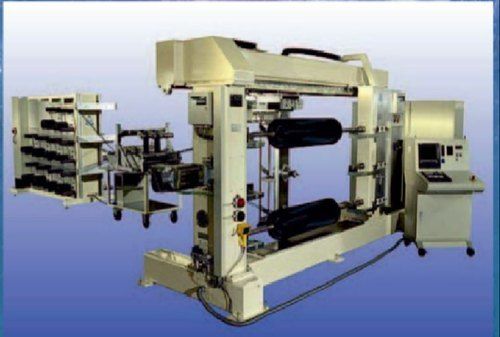

3/4- Axis Filament Winding Machine

Price 1000000 INR/ Piece

3/4- Axis Filament Winding Machine Specification

- Accessories

- Creel Stand, Resin Bath, Cutter Unit, Mandrel Support

- Motor Power

- 5 HP/Servo Motor (No. as per Axis)

- Plastic Processed

- FRP, GRP, Epoxy Resin, Carbon Fibre

- Temperature Range

- 10C - 50C (Ambient Operation)

- Efficiency (%)

- More Than 95%

- Automation Grade

- Automatic

- Model No

- FW-3400

- Speed

- 0.5-60 rpm (Variable)

- Production Capacity

- 25-40 Pipes/Day (Varies with Size)

- Usage & Applications

- Manufacture of Composite Pipes, Cylinders, Pressure Vessels, Tubes

- Driven Type

- Servo Motor Driven

- Installation Guideline

- Onsite installation & training by manufacturer support

- Frequency

- 50/60 Hz

- Type

- Filament Winding Machine

- Material

- Mild Steel, Aluminium Alloy, Stainless Steel (Body Components)

- Computerized

- Yes, PLC Based Control

- Automatic Grade

- Automatic

- Control System

- CNC/PLC with Touch Panel Interface

- Drive Type

- Electric

- Voltage

- 380V/415V, 3 Phase

- Power

- 4 kW - 8 kW (Depending on Model)

- Weight (kg)

- 1500 - 2200 kg

- Dimension (L*W*H)

- 4000mm x 1600mm x 1900mm (Approx.)

- Color

- Blue/White/Custom

- Warranty

- 1 Year

- Capacity

- Up to 500 mm Diameter; 4000 mm Length

- Features

- High Precision Servo Motors, Multi-Axis Synchronous Operation, User Friendly Interface, Data Storage

- Power Consumption

- 5-9 kWh

- Surface Finish

- Powder Coated / Painted

- Machine Type

- 3/4 Axis Filament Winding

- Operator Requirement

- Single Operator

- Axis Configuration

- 3/4 Axis Interpolated

- Winding Patterns Supported

- Hoop, Helical, Polar, Circumferential

- Safety Features

- Emergency Stop, Overload Protection, Enclosure Guards

- Storage Capability

- Recipe/Data Storage for 99+ Programs

- Software Support

- Optional CAD/CAM Integration

- Operation Mode

- Manual, Automatic, Semi-Automatic

- Max Winding Length

- Up to 4 Meters

- Max Fiber Tension

- Adjustable up to 60 N

- Number of Carriages

- 1 or 2 (Configurable)

- Mandrel Diameter Range

- 50 mm to 500 mm

3/4- Axis Filament Winding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 30-45 Days

About 3/4- Axis Filament Winding Machine

Application Excellence & Enhanced Features

This 3/4-Axis Filament Winding Machine is ideal for fabricating FRP, GRP, epoxy resin, and carbon fiber products like pipes, cylinders, tubes, and pressure vessels. Suitable for manufacturers aiming for precision and consistent results, it boasts adaptable winding patternshoop, helical, polar, and circumferential. Its automated, user-friendly operation, high storage capacity, and advanced safety features such as overload protection and enclosure guards, make it a noteworthy addition to any composite processing unit.

Sample Policy & Delivery Information

Samples are available upon request, enabling customers to assess machine adaptability prior to full order processing. List price applies for sample units, with seamless arrangements for arrival through the designated FOB port in India. The main domestic market covers extensive regions across India, ensuring prompt support and efficient delivery. This famed machinery comes with comprehensive onsite installation guidelines and training directly from the manufacturer, streamlining the buying and commissioning process.

FAQs of 3/4- Axis Filament Winding Machine:

Q: How can I personalise the winding patterns with this machine?

A: You can customise winding patterns such as hoop, helical, polar, and circumferential using the CNC/PLC touch panel interface, and further optimise them with optional CAD/CAM software integration.Q: What types of materials are suitable for use with the FW-3400 machine?

A: The FW-3400 supports a variety of composite materials including FRP, GRP, epoxy resin, and carbon fibre, making it versatile for the manufacture of pipes, cylinders, and pressure vessels.Q: Where can the 3/4-Axis Filament Winding Machine be installed?

A: This machine is suitable for installation in composite manufacturing facilities, pipe production units, and research or industrial workshops, with onsite installation and training provided by the manufacturer.Q: What is the process for order processing and delivery?

A: Once your order is confirmed, the machine will be processed and dispatched from our Indian FOB port, with sample policy options and arrival schedules discussed during the purchase process.Q: What are the main benefits of using a top-rated filament winding machine like the FW-3400?

A: Major benefits include outstanding precision, multi-axis synchronous operation, high efficiency, extensive programme storage, automatic safety systems, and adaptability to multiple production needs.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aerospace & Defence Equipments Category

Aerospace Trolley Type Curing Ovens and Pre-Heating Ovens

Price 100000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Material : Heavyduty Mild Steel with Insulated and Powder Coated Panels

Automatic Grade : Automatic

Type : Curing and Preheating Oven

Composite Curing Autoclave

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Material : Mild Steel / Stainless Steel

Automatic Grade : Automatic

Type : Curing Autoclave

Mobile Vacuum Systems

Price 100000 INR / Piece

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Material : Stainless Steel

Automatic Grade : Automatic

Type : Vacuum System

Prepreg Resin Impregnation Plant

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Material : Mild Steel

Automatic Grade : Automatic

Type : Prepreg Resin Impregnation Plant

Send Inquiry

Send Inquiry