Aerospace Vertical Hydroclaves- Aerohyd-V Series

Price 1000000 INR/ Unit

Aerospace Vertical Hydroclaves- Aerohyd-V Series Specification

- Installation Guideline

- Foundation Required, Assembly by Certified Technician

- Automation Grade

- Automatic

- Efficiency (%)

- Above 90%

- Speed

- Variable (Up to 1500 RPM)

- Driven Type

- Electric

- Temperature Range

- Up to 250C

- Frequency

- 50 Hz

- Accessories

- Safety Valve, Pressure Gauge, Digital Controller, Loading Tray

- Usage & Applications

- Aerospace composite curing, sterilization processes, lamination, material treatment

- Motor Power

- 3 HP

- Production Capacity

- As per batch processing requirements

- Model No

- Aerohyd-V Series

- Type

- Hydroclaves

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC Based Control Panel

- Drive Type

- Electric

- Voltage

- 415 V

- Power

- 5 kW

- Weight (kg)

- 1200 kg

- Dimension (L*W*H)

- 1800 x 1150 x 2460 mm

- Color

- Silver

- Warranty

- 1 year

- Capacity

- 500 Liters

- Features

- High Pressure Sealing, Uniform Heat Distribution, Digital Temperature Controller, Safety Interlock, Door Locking System

- Power Consumption

- 5 kWh

- Machine Type

- Vertical Hydroclave

- Surface Finish

- Polished

- Control Panel Display

- Digital LCD with Touchscreen

- Cooling System

- Water Jacketed for Rapid Cooling

- Gasket Material

- Silicone/EPDM High Temperature Resistant

- Door Type

- Manual/Automatic Sliding

- User Interface

- Multi-Language Support

- Cycle Time

- Up to 2 Hours (Dependent on Application)

- Steam Generation

- Integral Electric Steam Generator

- Chamber Type

- Vertical Cylindrical

- Safety Features

- Overpressure Protection, Emergency Release, Double Door Interlocks

- Internal Coating

- Corrosion Resistant Epoxy Coated

- Pressure Rating

- Up to 32 bar

Aerospace Vertical Hydroclaves- Aerohyd-V Series Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 30-45 Days

About Aerospace Vertical Hydroclaves- Aerohyd-V Series

Application Areas & Specific Usage

The Aerohyd-V Series Vertical Hydroclave is expertly engineered for aerospace composite curing, advanced sterilization processes, lamination, and high-specification material treatment. With its generous 500-liter capacity and rapid batch processing, it efficiently matches the demands of aircraft part manufacturers, R&D labs, and material testing facilities. Its trending technology supports uniform heat distribution and controlled temperature profiles, ensuring consistent results for high-performance aerospace components, making it indispensable for precise, large-scale operations.

Certifications, Samples & Sale Process

The Aerohyd-V Series adheres to stringent aerospace industry certifications, ensuring the finest quality for mission-critical applications. Sample units are available upon request for testing or validation before full purchase. Goods transport is managed securely and professionally, with installation guided by certified technicians upon handover. Payment terms are flexible, designed to align with customer needs, and sale prices are transparent. This assures hassle-free acquisition and setup for exporters, manufacturers, and suppliers across India.

FAQs of Aerospace Vertical Hydroclaves- Aerohyd-V Series:

Q: How does the Aerohyd-V Series ensure uniform heat distribution during operation?

A: The Aerohyd-V Series employs a water-jacketed cooling system and a high-performance electric steam generator, coordinated by a PLC-based control panel. These features work together with corrosion-resistant epoxy coatings and high-pressure sealing to provide consistent, uniform heat throughout the chamber, ensuring optimal treatment of aerospace materials.Q: What are the key safety features included in the Aerohyd-V Series Hydroclave?

A: Safety is prioritized with overpressure protection, emergency release mechanisms, double door interlocks, a robust door locking system, and high-temperature resistant gaskets. The integral digital controller and safety interlocks further enhance the protection of operators and equipment during demanding processes.Q: Where can the Aerohyd-V Series be installed for optimal use?

A: The hydroclave is suitable for installation in aerospace manufacturing facilities, testing laboratories, and R&D centers. Proper foundation preparation and assembly by certified technicians are essential to ensure safe and reliable operation in all industrial environments.Q: How does the ordering and delivery process work for this product?

A: Customers can request samples for validation, choose their preferred payment terms, and receive transparent sale prices. The product is securely transported and handed over, with certified technicians ensuring complete and correct installation at the customer site.Q: What specific applications does the Aerohyd-V Series serve in the aerospace industry?

A: This hydroclave is primarily used for aerospace composite curing, sterilization, lamination processes, and various advanced material treatments, providing high efficiency and reliability for critical processing tasks.Q: What are the benefits of the computerized PLC control panel?

A: The PLC-based digital control panel offers multi-language support, touchscreen operation, precise temperature and pressure adjustment, automated cycle management, and real-time display, streamlining operations and improving process reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aerospace & Defence Equipments Category

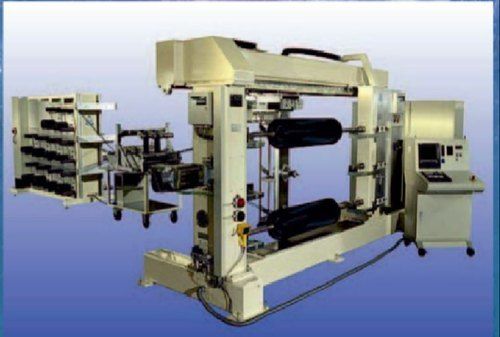

3/4- Axis Filament Winding Machine

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Unit

Type : Filament Winding Machine

Automatic Grade : Automatic

Material : Mild Steel, Aluminium Alloy, Stainless Steel (Body Components)

Drive Type : Electric

Mobile Vacuum Systems

Price 100000 INR / Piece

Minimum Order Quantity : 1 Unit

Type : Vacuum System

Automatic Grade : Automatic

Material : Stainless Steel

Drive Type : Electric

On-Site and Off-Site Calibration Services

Price 200000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : OnSite and OffSite Calibration Services

Automatic Grade : Manual

Material : Servicebased (No physical material applicable)

Aerospace Drop Bottom Furnaces

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Furnace

Automatic Grade : Automatic

Material : Mild Steel

Drive Type : Electric

Send Inquiry

Send Inquiry