AeroClave Series

Price 500000 INR/ Unit

AeroClave Series Specification

- Type

- Aerospace & Defence

- Material

- Stainless Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Human Machine Interface

- Drive Type

- Mechanical

- Color

- Silver

AeroClave Series Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Unit Per Month

- Delivery Time

- 2 Months

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

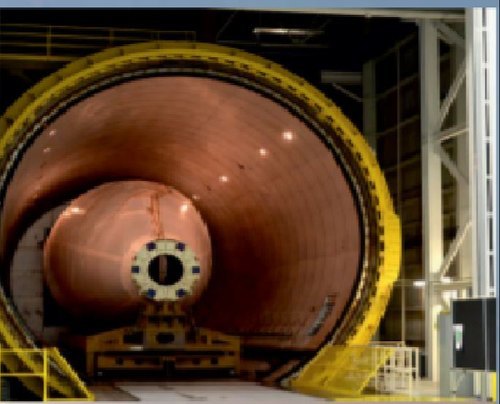

About AeroClave Series

Product Details:| Applications | For Carbon Fiber Composites/ Metal Bonded Composites |

| Automatic | Fully Automatic & Programmable |

| Vessel Design | As per ASME S.8 D.1 |

| Safety Measures | 4 Layer Safety & Redundancy |

| Rate of Pressurization | 0.5-1bar/min |

| Rate of Ht | 0.1-6 DegreeC/min.& upto 450 DegreeC |

| Design Pressure | Upto 40 Bar |

| Payload Capacity | 1 to 60 MT |

| Working Area | 0.5m to 8m |

| Heating | Direct Electrical/ Indirect Oil |

| Control | Computerized SCADA Control & Failure Detection Alarms |

| Special Features | Men-in-Clave Protection, Rupture Disc & Interlocks |

| Feedback System | Sensor based Closed Loop Feedback System |

| Uses | Especially for Flying Objects& MBCs |

We, Autotherm Group, India is a reputed Designers & manufacturers of High Quality Aerospace & Defense Equipments like Aerospace Composite Autoclaves, Rocket Motor (ROCASIN) Lining Autoclaves, Composite Rubber Lining Autoclaves, RTM mould Curing Autoclaves, Preform Mould Curing Autoclaves, Ultra-High Pressure Fluid Molding Hydroclaves, Vacuum Bagging System, On-Site/ Centralized Vacuum Units, Vacuum Heat Treatment Furnaces with NADCAP Certification, Vacuum Melting Furnaces, Vacuum Brazing Furnaces, VARTM/ RTM Mixing Machines, Resin Infusion System, Hot Hydraulic Presses, Vacuum Hot Hydraulic Presses, Prepreg/ Pre-Form Compression Molding Presses, Resin Impregnation Plants, Custom Design Filament Winding Units (3/5 Axis), Resin Production Plants, Custom Built Thermal & Process Equipments, Special Purpose Machines, Test Chambers, Reactors & Pressure Vessels, Custom Designed Continuous/ Batch Type Process Plants for Finishing / Assembly Lines. Also We Design, Manufacture, Test, and on-site commissioning of All types of Standard Thermal Products like Furnaces (Heat Treatment, Melting & Process), Ovens, Dryers, Autoclaves and Steam Sterilizers, Boilers and Steam Generators, Kilns and Continuous Hardening and Tempering Plant, Custom Designed Continuous Process Plants, Powder Coating/ Galvanizing Plants etc. We have International Standards like ISO and ASME U Stamp / CE Accrediations to provide world-class Quality Products. We are providing services in the field of Thermal & Process Solutions and Plant Automations for last 20 Years and still moving ahead very Fast and Curiously.

Callback

Advanced Control System

The AeroClave Series features a sophisticated Human Machine Interface (HMI), allowing for intuitive operation and real-time monitoring. Its computerized controls ensure high precision and consistent outcomes in critical aerospace and defence applications.

Reliable Stainless Steel Construction

Crafted from premium stainless steel, the AeroClave Series ensures maximum durability and corrosion resistance. Its robust construction and striking silver color make it ideal for the rigorous demands of the aerospace and defence industries.

FAQs of AeroClave Series:

Q: How does the AeroClave Series operate automatically in aerospace and defence settings?

A: The AeroClave Series utilizes a mechanical drive system combined with computerized automatic controls, enabling seamless operation with minimal manual intervention. Its advanced Human Machine Interface (HMI) allows users to monitor and manage processes efficiently, enhancing reliability in critical environments.Q: What benefits does the stainless steel construction provide for aerospace and defence applications?

A: Stainless steel offers exceptional durability and resistance to corrosion, making the AeroClave Series ideal for high-stress and harsh environments. It ensures long service life and maintains performance standards essential for aerospace and defence use.Q: When is the AeroClave Series typically used in industry operations?

A: The AeroClave Series is deployed during critical aerospace and defence processes requiring precise and reliable operation. Its automatic, computerized functionality is especially valuable in scenarios demanding minimal error and high efficiency.Q: Where is the AeroClave Series manufactured and available for export?

A: This advanced equipment is manufactured in India by a reputable exporter and supplier. It is available for global markets, offering reliable solutions to aerospace and defence sectors worldwide.Q: What is the process for controlling the AeroClave Series system during operation?

A: Control of the system is handled through its integrated Human Machine Interface (HMI), which provides interactive commands and status monitoring. The computerized system automates key functions, allowing operators to oversee performance and make adjustments as needed.Q: How can the AeroClave Series benefit aerospace and defence organizations?

A: Organizations benefit from the AeroClave Series through enhanced operational efficiency, automated controls, and superior durability. The combination of computerized precision and robust construction reduces downtime and maintenance, optimizing mission success rates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aerospace & Defence Equipments Category

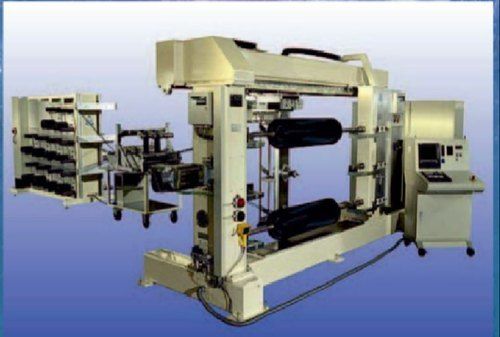

5/6 - Axis Filament Winding Machine

Price 150000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Filament Winding Machine

Warranty : 1 Year

Drive Type : Electric

Material : Highgrade Steel, Aluminum Components

3/4- Axis Filament Winding Machine

Price 1000000 INR / Piece

Minimum Order Quantity : 1 Unit

Type : Filament Winding Machine

Warranty : 1 Year

Drive Type : Electric

Material : Mild Steel, Aluminium Alloy, Stainless Steel (Body Components)

Aerospace Drop Bottom Furnaces

Price 1000000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Furnace

Warranty : 1 Year

Drive Type : Electric

Material : Mild Steel

VARTM/ RTM Resin Infusion System

Price 2000000 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Infusion System

Warranty : 1 Year

Drive Type : Electric

Material : Mild Steel

Send Inquiry

Send Inquiry